EN 15061 Sicurezza dei macchinari e linee processo nastri

| ID 3651 | | Visite: 14365 | Documenti Riservati Normazione | Permalink: https://www.certifico.com/id/3651 |

EN 15061 Sicurezza dei macchinari e linee processo nastri

ID 3651 | Rev. 2.0 del 13.05.2025 / Documento di approfondimento in allegato

Documento di approfondimento sui requisiti generali di sicurezza delle linee di lavorazione dei nastri metallici in accordo alla norma tecnica EN 15061:2022.

Documento aggiornato in accordo alla versione italiana della norma UNI EN 15061:2022.

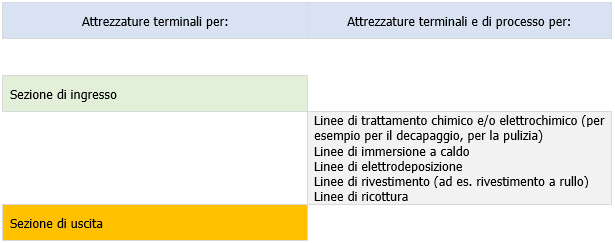

La norma si applica alle linee di lavorazione per il trattamento di nastri metallici, dal:

- punto di presa della bobina della sezione di ingresso (apparecchiature terminali, cfr. 3.2) lungo il

- processo (apparecchiature di trattamento e terminali, cfr. 3.3 e 3.2) fino al

- punto di presa della bobina della sezione di uscita o interfaccia con altre linee (apparecchiature terminali), cfr. figura 1.

Figura 1 - Attrezzature terminali e di processo

Se i processi sopraindicati sono combinati con processi che non rientrano nell'ambito di applicazione della norma, la EN 15061:2022 può essere usata come linea guida.

La norma EN 15061:2022 non copre:

- attrezzature per processi termici, ad es. in accordo alle norme della serie EN 746;

- essiccatori e forni secondo EN 1539;

- sistema di trasporto del coil prima del punto di presa in carico del coil nella sezione di ingresso e dopo il punto di presa in carico del coil nella sezione di uscita, ad es. trasportatori a gancio, carriponte, carrelli elevatori e autocarri ferroviari e altro veicoli;

- impianti di rigenerazione acida;

- impianti di rigenerazione che non sono parte integrante della linea di lavorazione del nastro;

- attrezzature per lo stoccaggio dei coils;

- gabbie di laminazione in accordo alla EN 15094;

- pinze, supporti e sistemi per la manutenzione dei nastri;

- tecnologia di processo separata (ad es. sistema ad aria compressa, trattamento dell'acqua e trattamento della laminazione lubrificante);

- sistema di pulizia separato per l'aria di scarico;

- sistemi antincendio.

Entrata in vigore il 09 Marzo 2022.

Recepita in Italia con la norma UNI EN 15061:2022 entrata in vigore il 21 Luglio 2022.

L’edizione EN 15061:2022 è in attesa di armonizzazione per la Direttiva Macchine 2006/42/CE, è attualmente armonizzata l’edizione EN 15061:2007+A1:2008.

[...]

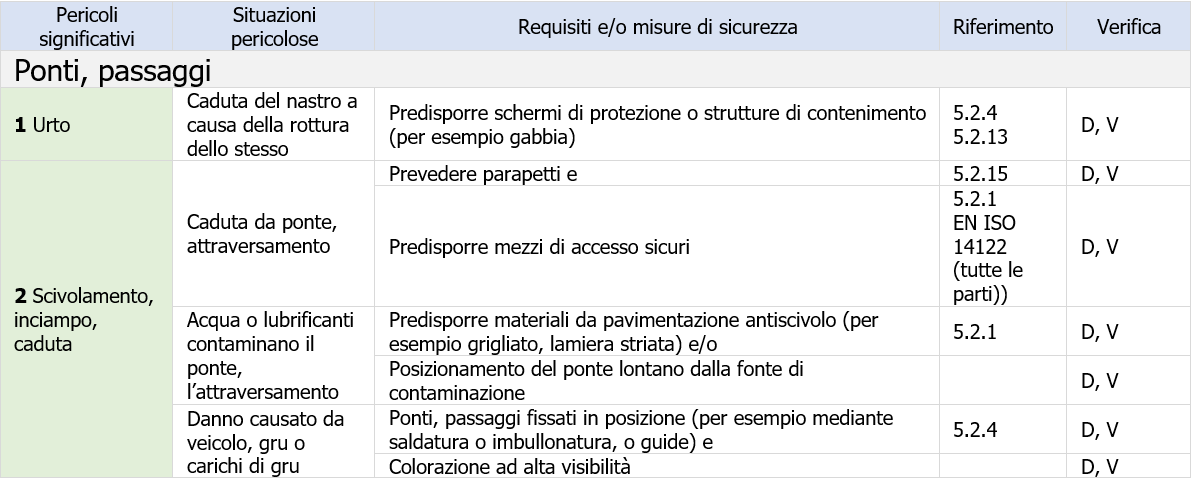

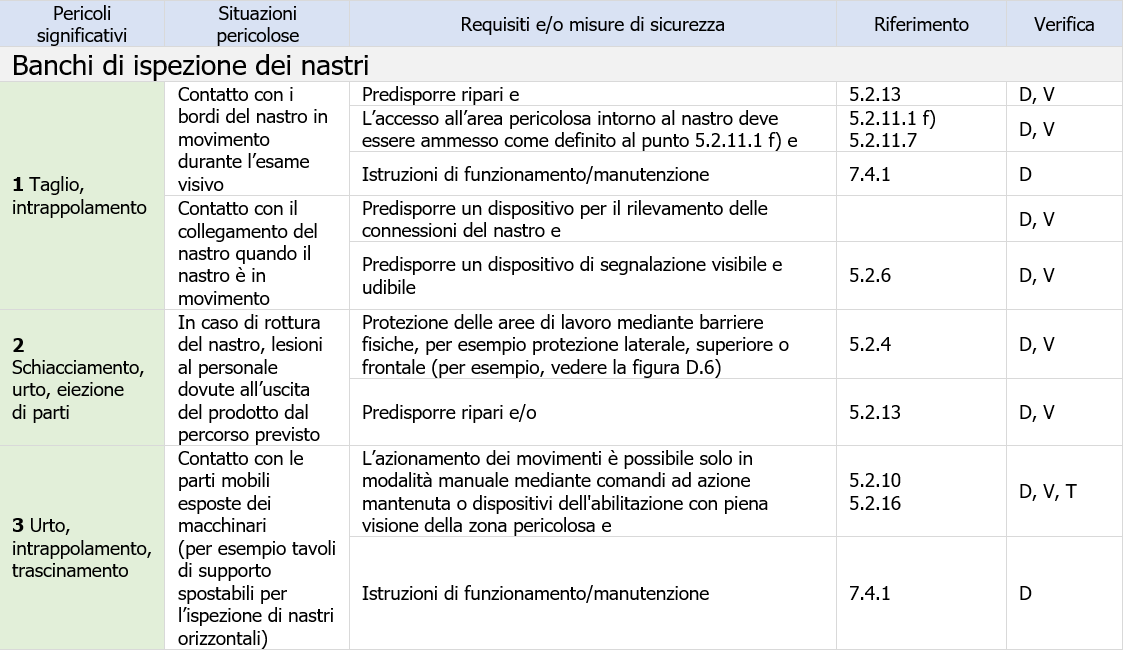

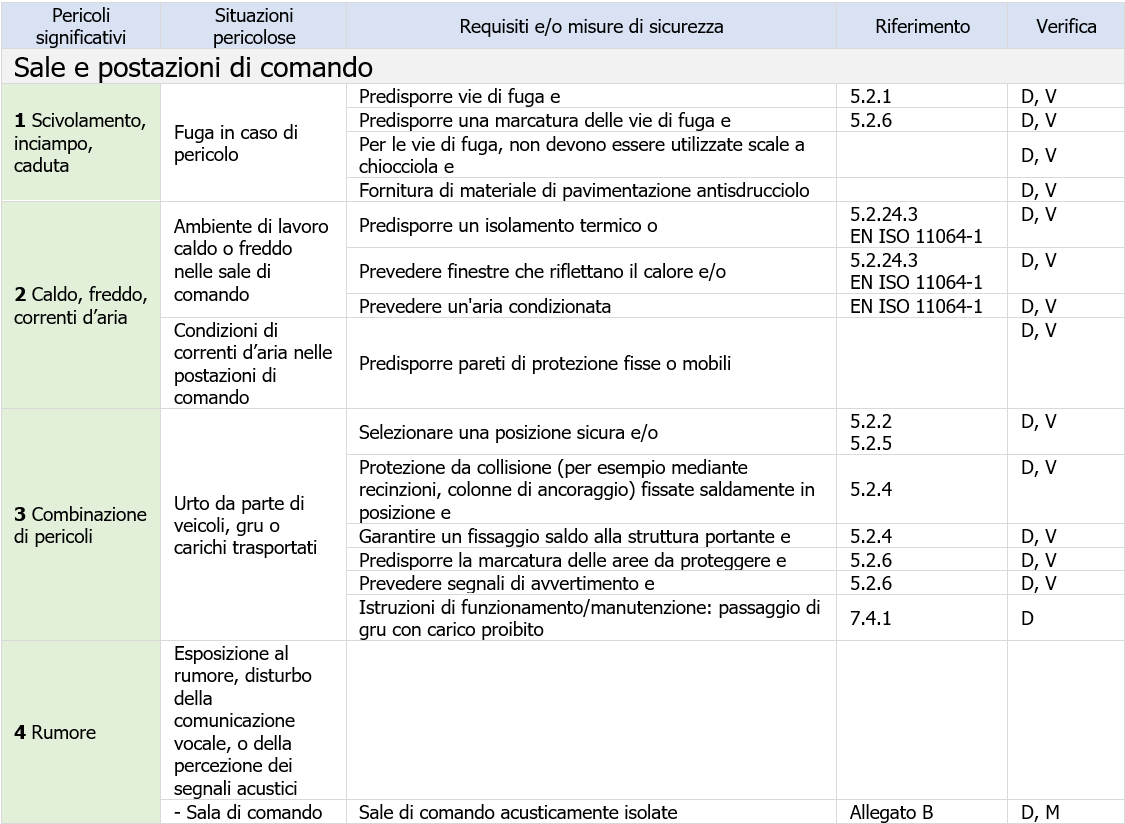

Elenco di pericoli significativi, situazioni pericolose, requisiti di sicurezza e/o misure di protezione/riduzione del rischio per le attrezzature terminali

Il prospetto 4 è strutturato come segue:

a) la colonna 1 identifica i pericoli significativi;

b) la colonna 2 descrive le situazioni pericolose;

c) la colonna 3 specifica i requisiti e/o le misure di sicurezza per evitare o minimizzare i pericoli e le situazioni pericolose. Sono illustrate come misure combinate o come opzioni;

d) la colonna 4 fa riferimento ai punti o alle norme pertinenti che definiscono le misure.

Tutti i riferimenti illustrati sono applicabili a tutte le misure salvo dove diversamente indicato.

Nell'applicazione dei requisiti e/o delle misure di sicurezza, si dovrebbe considerare che possono presentarsi contemporaneamente pericoli diversi;

e) la colonna 5 identifica i metodi di verifica da utilizzare per dimostrare la conformità; le basi sono, per esempio, disegni, descrizioni delle funzioni e/o calcoli. Le abbreviazioni delle verifiche previste D (disegni/calcoli), V (visiva), T (test/controllo) e M (misurazione) sono definite come segue:

V: Esame visivo.

T: Una prova funzionale/verifica/convalida per verificare che le caratteristiche fornite eseguano la propria funzione in modo tale che il requisito sia soddisfatto.

M: Le misurazioni sono necessarie per verificare che i requisiti siano soddisfatti entro i limiti specificati.

[...]

[...]

[...]

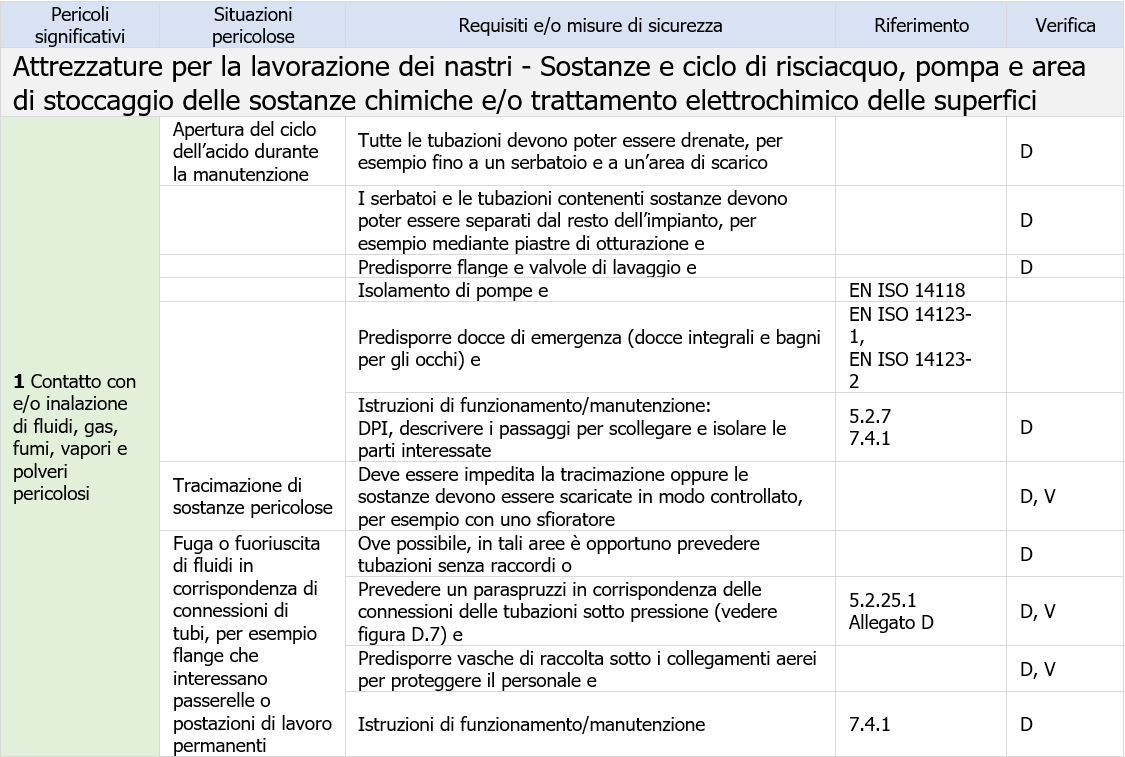

Elenco di pericoli significativi, situazioni pericolose, requisiti di sicurezza e/o misure di protezione/riduzione del rischio per le attrezzature di processo

Il prospetto 5 è strutturato come segue:

a) la colonna 1 identifica i pericoli significativi;

b) la colonna 2 descrive le situazioni pericolose;

c) la colonna 3 specifica i requisiti e/o le misure di sicurezza per evitare o minimizzare i pericoli e le situazioni pericolose. Sono illustrate come misure combinate o come opzioni;

d) la colonna 4 fa riferimento ai punti o alle norme pertinenti che definiscono le misure.

Tutti i riferimenti illustrati sono applicabili a tutte le misure salvo dove diversamente indicato.

Nell'applicazione dei requisiti e/o misure di sicurezza, si dovrebbe considerare che possono presentarsi contemporaneamente pericoli diversi;

e) la colonna 5 identifica i metodi di verifica da utilizzare per dimostrare la conformità, per esempio mediante l’uso di disegni, descrizioni delle funzioni e/o calcoli. Le abbreviazioni sono definite come segue:

V: Esame visivo.

T: Una prova funzionale/verifica/convalida per verificare che le caratteristiche fornite eseguano la propria funzione in modo tale che il requisito sia soddisfatto.

M: Le misurazioni sono necessarie per verificare che i requisiti siano soddisfatti entro i limiti specificati.

[...]

[...]

[...] segue in allegato

Fonti

EN 15061:2022

Direttiva Macchine 2006/42/CE

Certifico Srl - IT | Rev. 2.0 2025

©Copia autorizzata Abbonati

Matrice Revisioni:

| Rev. | Data | Oggetto | Autore |

| 2.0 | 13.05.2025 | Aggiornato UNI EN 15061:2022 Versione IT | Certifico Srl |

| 1.0 | 03.02.2023 | Aggiornato in accordo alla EN 15061:2022 | Certifico Srl |

| 0.0 | 20.02.2017 | -- | Certifico Srl |

Collegati

Direttiva Macchine 2006/42/CE

Norme armonizzate Direttiva macchine 2006/42/CE (DM)

Valutazione dei rischi EN ISO 12100: esempio operativo

ANSI B11.0-2020 e ISO 12100:2010: Valutazione rischi macchine

EN ISO 12100 e ISO/TR 14121-2: Esempio applicazione Valutazione del rischio

Direttiva macchine: Il Manuale di Istruzioni, redazione e validazione

Certifico MIUM & MIA SUITE 2023

| Descrizione | Livello | Dimensione | Downloads | |

|---|---|---|---|---|

| EN 15061 2022 Sicurezza dei macchinari e linee processo nastri Rev. 2.0 2025.pdf Certifico Srl - Rev. 2.0 2025 |

1405 kB | 67 | ||

| EN 15061 2022 Sicurezza dei macchinari e linee processo nastri Rev. 1.0 2023.pdf Certifico Srl - Rev. 1.0 2023 |

834 kB | 243 | ||

| EN 15061 Safety requirements for strip processing line machinery and equipment.pdf Certifico Srl - Rev. 0.0 2017 |

732 kB | 398 |

Tags: Normazione Norme Direttiva macchine Abbonati Normazione